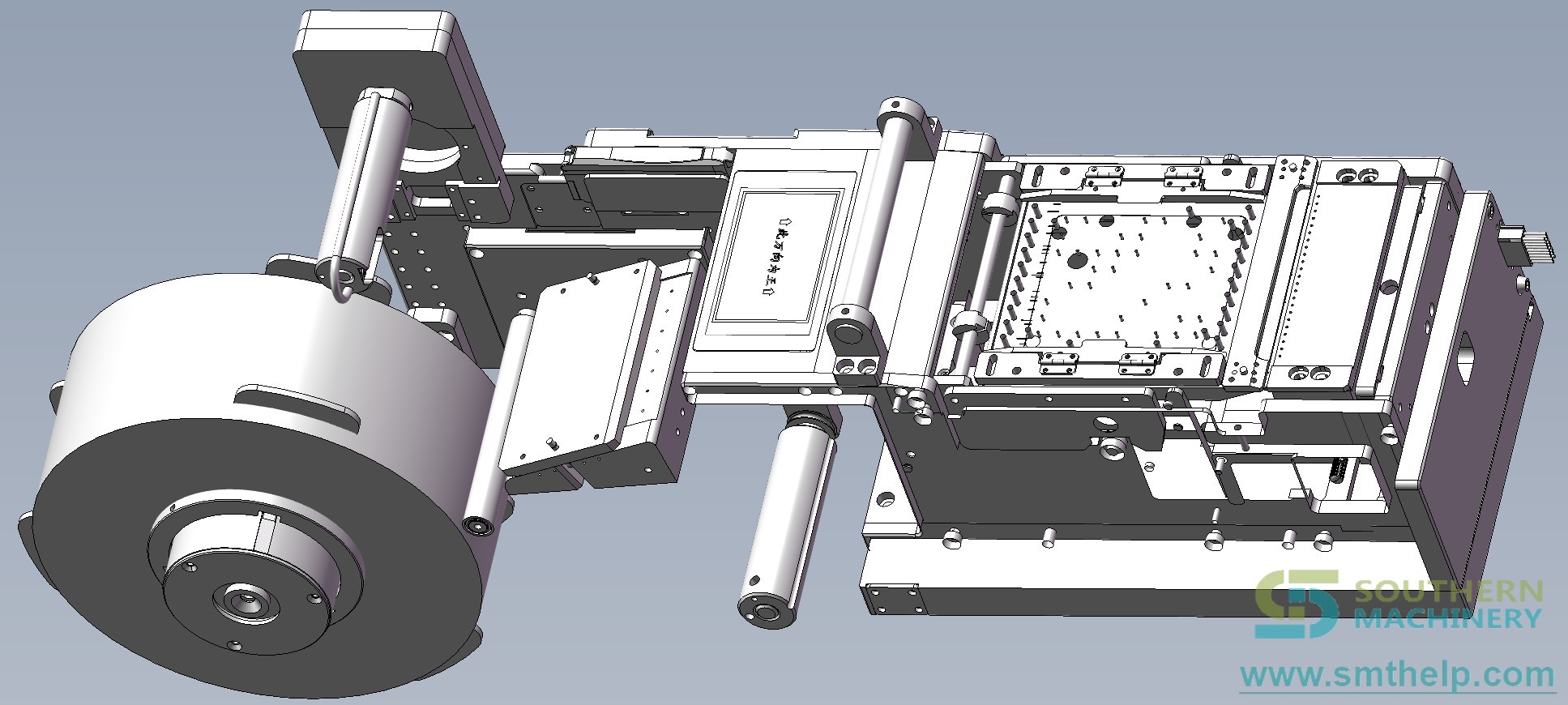

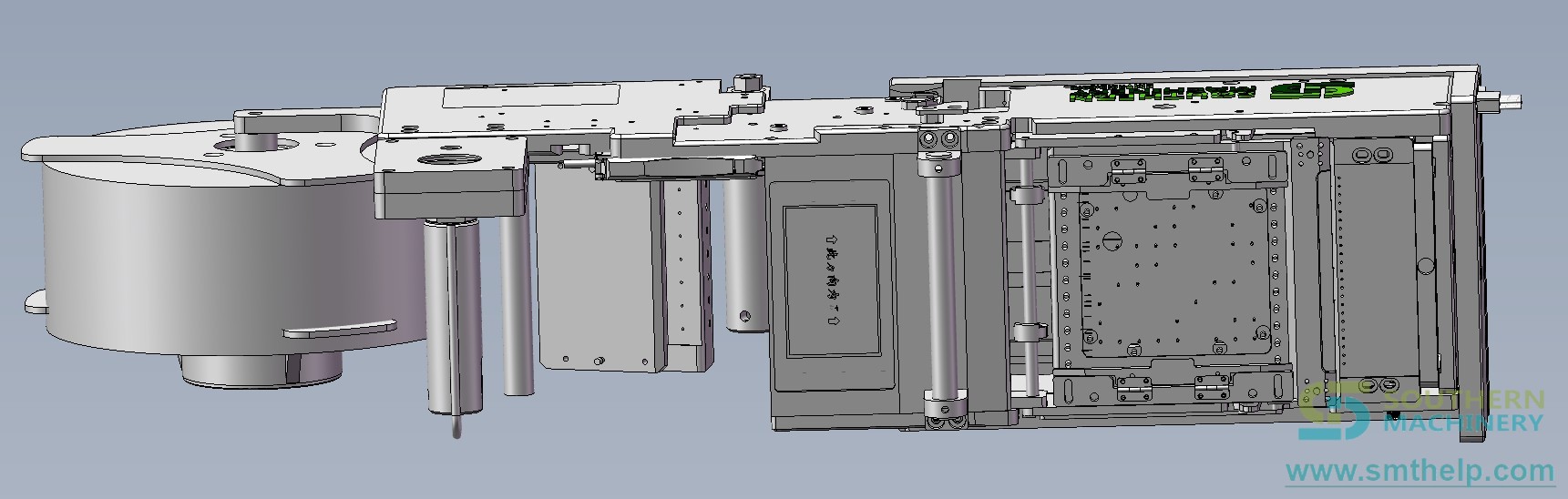

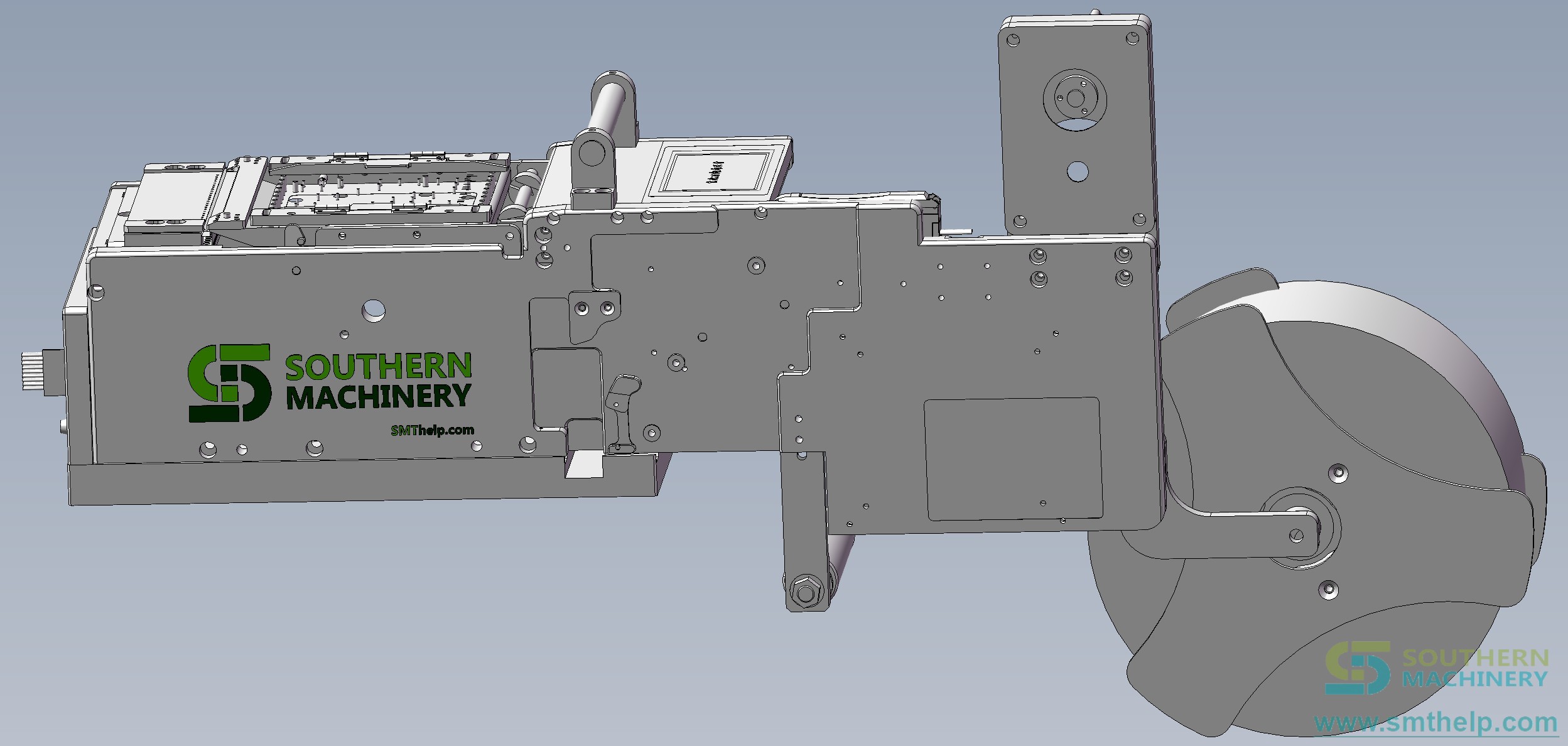

Label Feeder

Label Feeder for SMT/AI /Customized Machine

Features:

- Automated addition of QR code labels to PCB boards for SMT Production MES Online management

- Compact design with small footprint

- Easy to use and integrate with existing SMT lines

- Customizable to accommodate a wide range of label sizes and materials

- High accuracy and repeatability (±0.2mm)

Benefits: - Improved traceability: QR code labels provide real-time tracking of components and assemblies, reducing errors and waste.

- Increased efficiency: Automatic label feeding eliminates manual labor, saving time and resources.

- Enhanced quality: Precise label placement ensures accurate alignment and adhesion, improving product reliability.

- Reduced downtime: Compatible with a wide range of SMT machines, minimizing downtime for changeovers.

Advantages: - Low investment cost: Affordable solution for enhancing traceability and efficiency.

- Compact design: Fits seamlessly into existing production lines, minimizing space requirements.

- Versatility: Can be used for a variety of materials, including paper labels, protective films, and double-sided tape.

- Industry-leading technology: Incorporates advanced PLC controls and stepper motors for precise and reliable operation.

Evidence: - Over 1,000 units installed worldwide in leading EMS factories.

- Customer testimonials attest to improved productivity, reduced errors, and enhanced traceability.

Industry Applications: - SMT Production MES Online management

- Electronic assembly

- Printed circuit board (PCB) manufacturing

- Automotive electronics

- Consumer electronics

- Medical devices

Challenges and Pain Points: - Manual label feeding is time-consuming and error-prone, leading to production delays and quality issues.

- Inaccurate label placement can result in misalignment, rework, and potential failures.

- Lack of traceability can hinder troubleshooting and product recall efforts.Here are some additional details about the Label Feeder for SMT/AI/Customized Machine from Southern Machinery:

Challenges Solved: - Eliminate Manual Label Feeding: Reduce production delays and errors associated with manual processes.

- Ensure Accurate Label Placement: Improve product reliability by eliminating misalignment and ensuring proper adhesion.

- Enhance Traceability: Enable real-time tracking of components and assemblies, facilitating troubleshooting and product recall efforts.

Why Choose Our Label Feeder? - Increased Traceability: QR code labels provide real-time visibility into your production process, reducing errors and waste.

- Improved Efficiency: Automatic label feeding eliminates manual labor, saving time and resources.

- Enhanced Quality: Precise label placement ensures accurate alignment and adhesion, improving product reliability.

- Reduced Downtime: Compatible with a wide range of SMT machines, minimizing downtime for changeovers.

- Industry-Leading Technology: Our feeder incorporates advanced PLC controls and stepper motors for precise and reliable operation.

Specification:

| Dimension | LxWxH | 650x165x320mm |

| Weight | 7.5Kg | |

| Applicable Paper Label | Bottom paper less than 60mm/80mm/100mm | |

| Bottom paper thickness | 0.05mm-0.08mm | |

| Materials | Material Type | Paper label, protective film, foam, double-sided adhesive tape, conductive adhesive, or coil packaging materials such as copper foil and steel sheet |

| Material size | Min>3mm, MAX<width of bottom paper | |

| Inner diameter of material tray | Standard 3-inch core, Other specifications can be customized | |

| The maximum load of the tray | <3Kg | |

| Electric Sysetm | Power | 24V |

| Average /peak Current | 1.5A/3A | |

| Pressure | 0.4-0.6Mpa | |

| Operation Method | Buttom/Touch Screen | |

| Machine Connection | 8-core ø16mm aviation plug | |

| Communication Method | IO communication or self-control | |

| Control Method | PLC | |

| Drive Mode | Stepper Motor | |

| Motor Type | 42 type | |

| Max Motor Speed | 600 RPM | |

| Working Data | Cycle Time | 1S |

| Accuracy | ±0.2mm |

https://file.autoinsertion.com/SMT%20machine%203D%20Drawing%20in%20Html/SMT%20label%20feeder.html#/

[!info] SMT feeder designer

Revolutionize your SMT assembly line with our expert SMT feeder designer services.

https://ph.smthelp.com/album/smt-feeder-designer.hBn

https://youtu.be/AvI9rTkF748?si=1f-helhzEe5MMADV

https://youtu.be/IMasZb-Zm8U?si=um-dlS-rC10TJR9M

Connect with us, follow our journey, and stay updated on our latest innovations through our social media channels:

- LinkedIn Company Page

- LinkedIn Profile

- YouTube Channel

- Browse our machine catalog at file.autoinsertion.com and find machine photos at ph.smthelp.com.

Experience the Southern Machinery difference today – your trusted partner in delivering excellence and efficiency to your PCB assembly line. Join our global network of satisfied customers who have elevated their production capabilities with our cutting-edge solutions.

Southern Machinery – Shaping the Future of Electronics Manufacturing.

[!info] SMT solution provider

We specialize in Auto Insertion machine and SMT equipments, provide spare parts, sub-assembly, retrofit kit, repair kit, upgrading, training, overhaul service.

https://www.youtube.com/c/Smthelping

https://twitter.com/smtspecialist

[!info] Explore Recent

One stop solutions for Smart EMS factory

https://ph.smthelp.com/explore/recent

https://file.autoinsertion.com/?dir=/SMT%20machine%203D%20Drawing%20in%20Html

[!info] https://www.linkedin.com/company/smtmachine

发表评论