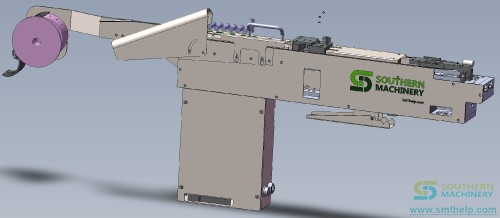

Radial Feeder

RTF-2002 Radial Tape Feeder

This feeder is designed for use with SMT mounter machines, specifically for feeding THT tape components such as capacitors, safety capacitors, LEDs, keys, triodes, and hardware parts. It is suitable for a wide range of mounter brands including Panasonic, Juki, Fuji, ASM, Universal, and many others. The feeder features height mechanical matching and communication capabilities to ensure seamless integration with the machine.

Before cutting, ensure that the lead is clamped properly to prevent any component from jumping or causing deformation on the cutting surface. The entire CCL mechanism features an integrated floating design, allowing for easy and quick adjustment of lead length after cutting. Simply loosen the screw of the green adjustment block and adjust the height accordingly.

Features:

- Designed for use with SMT mounter machines

- Specifically for feeding THT tape components such as capacitors, safety capacitors, LEDs, keys, triodes, and hardware parts

- Suitable for a wide range of mounter brands including Panasonic, Juki, Fuji, ASM, Universal, and many others

- Features height mechanical matching and communication capabilities to ensure seamless integration with the machine

- Integrated floating design allows for easy and quick adjustment of lead length after cutting

- Dimensions: 680mm L x 80mm W x 140mm H

- Power supply: 110/220V

- Cycle time: ≤ 0.8 seconds

- Controlled by PLC & sensors

- Built with high-quality materials for durability and longevity

- Comes with a user-friendly interface for easy operation and monitoring

- Offers precise feeding of components to minimize errors and increase efficiency

- Can handle a variety of tape thicknesses, including 12.5, 18, 25, and 37.5 mm

- Includes safety features such as emergency stop button and protective cover for operator's safety

- Requires minimal maintenance and can be easily cleaned and maintained

- Compatible with various types of THT tape reels, including standard and non-standard sizes

- Provides real-time feedback on the feeding process through LED indicators and error messages

- Can be customized to meet specific requirements and preferences of the user

- Provides a reliable and consistent feeding mechanism for optimal performance

- Offers a compact and space-saving design to fit in any production environment

- Can be easily installed and set up with minimal training required

- Meets industry standards and certifications for quality and safety

- Provides excellent value for money with its advanced features and durability

- Comes with a comprehensive warranty and customer support for peace of mind

- Can be integrated with other equipment and systems for seamless automation

- Offers a fast and efficient solution for high-volume production needs

- Provides a hassle-free experience for the user with its user-friendly interface and easy maintenance.

Contact: info@smthelp.net

Work video: https://www.bilibili.com/video/av64663700/?p=4

https://file.autoinsertion.com/SMT%20machine%203D%20Drawing%20in%20Html/SMT%20Radial%20Taped%20Feeder%20S%20Bend%20Designed%20by%20Southern%20Machinery.SLDPRT.html#/

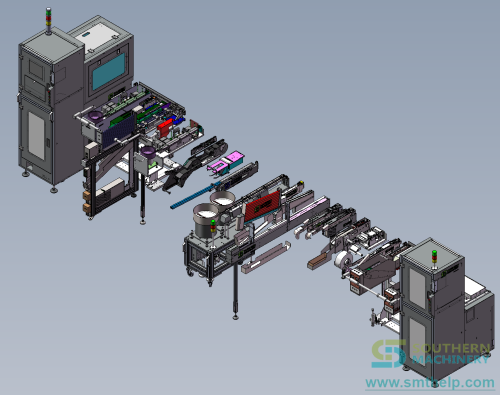

Product Introduction: Southern Machinery Radial Feeder

Overview:

Southern Machinery introduces its latest innovation, the Radial Feeder, designed to revolutionize the PCB assembly process. This feeder is a cutting-edge solution for feeding through-hole Radial taped components (THT Radial taped components) in various placement machines, catering to the evolving needs of the electronics manufacturing industry.

Product Details:

The Radial Feeder boasts a range of features and benefits that make it a standout choice for manufacturers seeking efficiency and precision in the assembly process.

- Advanced Design and Compatibility:

- The feeder is meticulously designed to seamlessly integrate with a variety of placement machines, including but not limited to JUKI, Yamaha, FUJI, Panasonic, ASM/Siemens, Mirae, and more.

- Versatile compatibility ensures ease of integration into existing assembly lines, enhancing flexibility for manufacturers.

- Superior Performance:

- Precision-engineered to deliver consistent and accurate component feeding, minimizing errors in the PCB assembly process.

- The feeder adapts to various SMT Mounters on the market, showcasing its adaptability and reliability.

- Power Efficiency:

- The Radial Feeder sets itself apart by exclusively operating on 24VDC power, emphasizing energy efficiency without compromising performance.

- This power requirement aligns with modern industry standards, contributing to eco-friendly and cost-effective manufacturing practices.

- Industry Applications:

- Ideal for use in smart EMS factories and electronic product manufacturing processes, the Radial Feeder enhances the efficiency and speed of the assembly line.

- Widely applicable in the production of THT product, ensuring a smooth and reliable PCB assembly.

Benefits:

The Southern Machinery Radial Feeder offers several key benefits that address the pain points in the PCB assembly process:

- Increased Productivity:

- The precision and efficiency of the Radial Feeder contribute to a significant boost in overall manufacturing productivity.

- Reduces downtime and enhances the output of electronic products.

- Cost Savings:

- Energy-efficient operation at 24VDC results in reduced power consumption, leading to cost savings for manufacturers.

- Minimizes the risk of component wastage through precise feeding, optimizing resource utilization.

- Reliability and Consistency:

- Ensures a consistent and reliable feeding mechanism, reducing the likelihood of errors and defects in the assembly process.

- Contributes to the overall quality and reliability of electronic products.

Conclusion:

In conclusion, Southern Machinery’s Radial Feeder is a game-changer in the field of SMT and THT feeders. Its advanced design, compatibility with various placement machines, power efficiency, and industry applications make it a valuable addition to any smart EMS factory. With a focus on precision and productivity, this feeder sets the standard for efficient PCB assembly.

Note:

Southern Machinery also offers a range of other feeders, including Axial, Tube, Bowl, Tray, Bulk, and Vibrate feeders, providing a comprehensive suite of solutions for diverse manufacturing needs.

Product Manual Link

Product Design and Manufacturer Link

Specification:

| Dimension | LxWxH | 720x92x165mm |

| Weight | 10Kg | |

| Materials | Material Type | Capacitors, Terminals, Springs, Resistors etc |

| Material Size | 2x2x3-15x15x30mm | |

| Lead Cutting Length | 3-6mm(Adjustment) | |

| Tape Pitch | 12.7mm /15mm | |

| Electric Sysetm | Power | 24V |

| Average /peak Current | 4A/6A | |

| Pressure | 0.4-0.6Mpa | |

| Operation Method | Button/Touch Screen | |

| Machine Connection | 8-core ø16mm aviation plug | |

| Communication Method | IO communication or self-control | |

| Control Method | PLC | |

| Drive Mode | Stepper Motor | |

| Motor Type | 42 type/86 type | |

| Max Motor Speed | 600 RPM | |

| Working Data | Cycle Time | 1S |

| Accuracy | ±0.2mm |

Below links you can learn more about our feeders:

1, Catalog

Introduce Odd Feeder.pdf (autoinsertion.com)

Radial Feeder User Manual.pdf (autoinsertion.com)

2, 3D Drawing

file.autoinsertion.com/SMT machine 3D Drawing in Html/Bulk Feeder S-MVF01.html

file.autoinsertion.com/SMT machine 3D Drawing in Html/JUKI JM Radial Feeder.html

[file.autoinsertion.com/SMT machine 3D Drawing in Html/Feeder cart-Bowl Axial Radial Tube.html](https://file.autoinsertion.com/SMT%20machine%203D%20Drawing%20in%20Html/Feeder%20cart-Bowl%20Axial%20Radial%20Tube.html)

3,Working Video

https://youtu.be/IoeB4vBKI-o?si=P_XSKmex3aKQsD0M

https://youtu.be/ylto3gxp1PI?si=fffh6Hp3fjri6V22

4,Pictures

SMT feeder designer – SMT THT machine design and manufacturing (smthelp.com)

Radial Feeder Test Trial Checklist

1. Pre-Installation Phase

- [ ] Confirm receiving Radial Feeder shipment.

- [ ] Inspect the package for any visible damage caused during transportation.

- [ ] Verify all the components of the Radial Feeder are included as per the packing list.

2. Installation Phase

- [ ] Follow the provided instructional guide to install the Radial Feeder.

- [ ] Record whether installation is quick and straightforward.

- [ ] Document any problems or difficulties encountered during installation.

3. Operational Testing

- [ ] Once installed, check power connection and ensure the unit powers up correctly.

- [ ] Verify that the Radial Feeder interfaces correctly with the JUKI JM series machine.

- [ ] Initiate a dry run, checking if the feeder progresses smoothly.

4. Performance and Compatibility

- [ ] Start a production test run. Measure the performance efficiency and record the data.

- [ ] Check if the Radial Feeder is able to feed components at a speed that matches your working pace.

- [ ] Test the device’s compatibility with different types of components as per your design requirements.

5. User Experience

- [ ] Evaluate the ease of use and user-friendliness of the device.

- [ ] Gather feedback from operators regarding their experience using the Radial Feeder.

6. Post-Trial Evaluation

- [ ] Collate and analyze recorded data from the trial run.

- [ ] Check overall improvement/difference in productivity with the inclusion of the Radial Feeder.

- [ ] Evaluate overall satisfaction with performance, compatibility, and ease-of-use.

https://file.autoinsertion.com/SMT%20machine%203D%20Drawing%20in%20Html/SMT%20Radial%20tape%20feeder%20with%20small%20E-cap.html#/

[!important]

Any questions about the design and application of Radial Feeder, please feel free to leave them in the comments section at the bottom and share them with us.~

[!info] SMT solution provider

We specialize in Auto Insertion machine and SMT equipments, provide spare parts, sub-assembly, retrofit kit, repair kit, upgrading, training, overhaul service.

https://www.youtube.com/c/Smthelping

https://twitter.com/smtspecialist

[!info] Explore Recent

One stop solutions for Smart EMS factory

https://ph.smthelp.com/explore/recent

https://file.autoinsertion.com/?dir=/SMT%20machine%203D%20Drawing%20in%20Html

[!info] https://www.linkedin.com/company/smtmachine

发表评论